Portable Simunitions Shoot House

$0.00

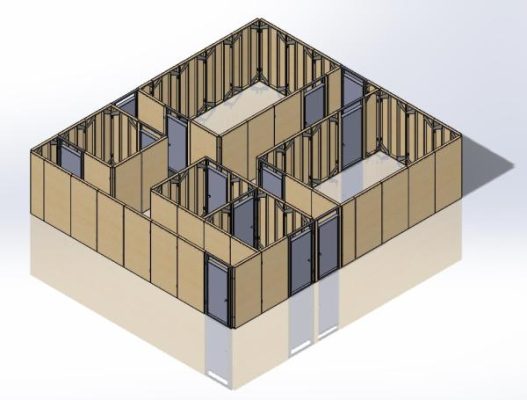

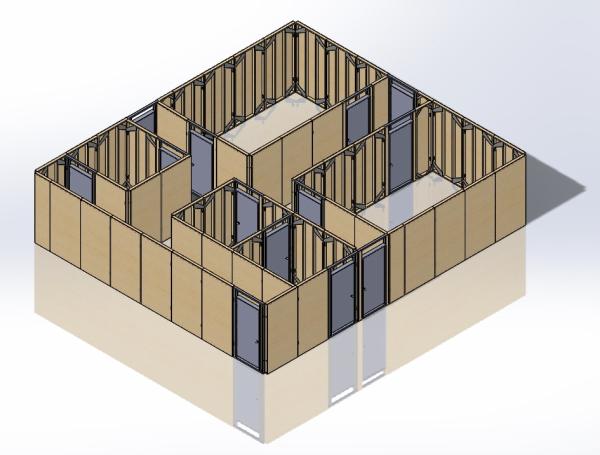

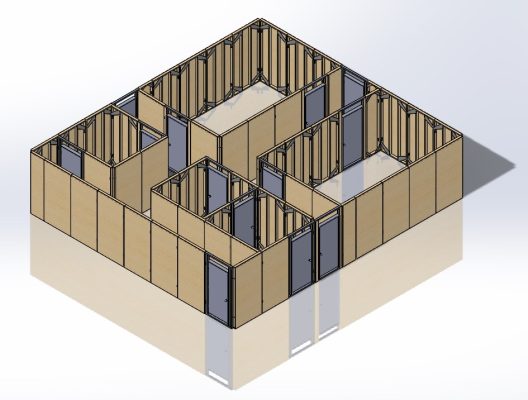

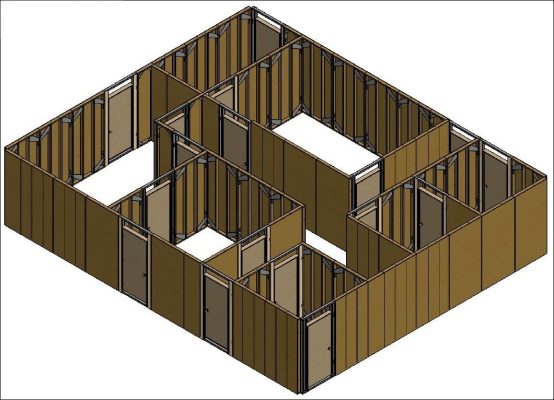

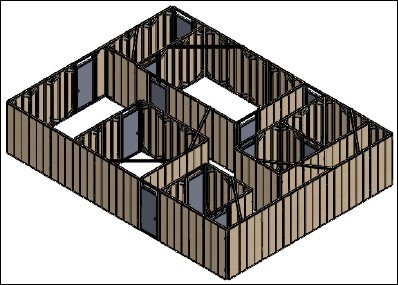

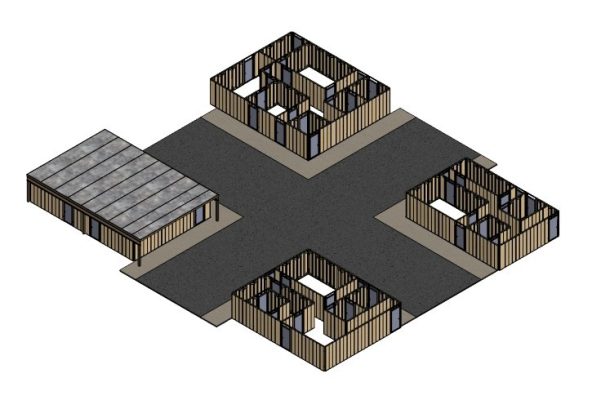

Designed to be used EXCLUSIVELY with Simunitions rounds, the MGM Portable Simunitions Shoot House is one of the most innovative training structures in the firearms training world today. Comprised of 3 different wall/door panels and 3 different steel corner/connection pieces, the simplistic design will allow a VERY legitimate “building clearing” training scenario to be set up in minutes, in virtually any location, and on any surface.

CAUTION!

The MGM Portable Simunitions Shoot House is NOT DESIGNED FOR LIVE FIRE AMMUNITION! This system is designed ONLY for SIMUNITIONS weapons and rounds. Use of any live fire ammunition in this structure will most certainly result in DEATH or serious injury.

MGM’s experience with live fire facilities since 1994, and manufacturing in general since 1973 puts us in a unique position to design a VERY durable portable system that can last for years. The main problem with wooden components is that they are frequently assembled “ASAP”, with nail guns or staple guns. There is no serious connection there, and the smooth shank of the nails or staples allow the wood sheets to come off the wood frames in very short order. MGM uses screws exclusively, at every connection point, instead of smooth shank nails or staples. Additionally, we predrill every screw hole, to keep the screws from splitting the wood. Inexperienced fabricators won’t grasp the significance of the screws, and they certainly won’t have a clue as to why we predrill every hole! As with our steel target line, MGM is about quality and value.

The first wooden wall panels that MGM designed, fabricated, delivered, and erected were 40’ tall, and erected in the desert for the Army at Ft. Irwin National Training Center outside Barstow, CA. The fabricated components, when assembled presented a facade that represented a middle eastern village, complete with minaret. The Army used this facade for live fire convoy training.

Designed to be used EXCLUSIVELY with Simunitions rounds, the MGM Portable Simunitions Shoot House is one of the most innovative training structures in the firearms training world today. Comprised of 3 different wall/door panels and 3 different steel corner/connection pieces, the simplistic design will allow a VERY legitimate “building clearing” training scenario to be set up in minutes, in virtually any location, and on any surface.

Designed to be used EXCLUSIVELY with Simunitions rounds, the MGM Portable Simunitions Shoot House is one of the most innovative training structures in the firearms training world today. Comprised of 3 different wall/door panels and 3 different steel corner/connection pieces, the simplistic design will allow a VERY legitimate “building clearing” training scenario to be set up in minutes, in virtually any location, and on any surface.

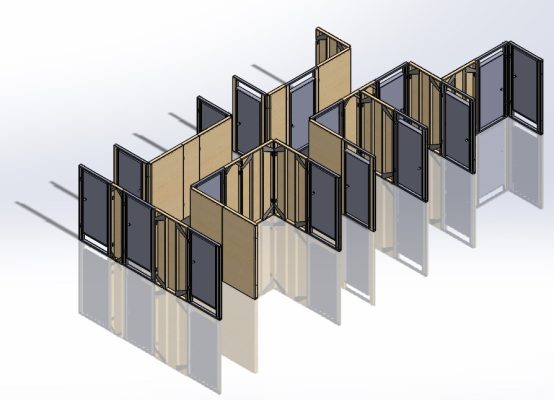

The MGM Simunitions Shoot House is easily reconfigurable, and legitimately portable. The wall panels use standard 2 x 4 lumber and standard 7/16” OSB (oriented strand board, or wafer board) as the main components. From there, we incorporate screws EXCLUSIVELY for all connections. Each panel connect to other panels with ONLY two ½” diameter bolts, and we provide battery powered industrial duty impact wrenches for the assembly! Additionally, at the locations where the ½” structural bolts go through the side boards (to connect to other panels) we have permanently installed ¼” thick steel plates that are 8” tall. These will prevent the panel edge 2 x 4s from becoming damaged, and make it virtually impossible for the assemblers to damage the panel during assembly or disassembly. The OSB sheet acts as a structural diaphragm on one side of the frame as is commonly done in commercial construction. We have also added steel reinforcement gussets (18” long) on the side opposite the OSB, at each corner, to further prevent “racking” of the panels. The racking (during handling and assembly/disassembly) is what truly damages wood structures and connections. We have thought this through. We have done this before. We have fixed the problems.

The Door Panels are the standard 48” wide, but the frames are made of structural steel tubing. Connecting holes are exactly the same as for all the other panels, so the Door Panels will fit between panels of any size, at any location in your building. The opening in the structural tube frame is the exact size for a prehung door, so if you team needs to breach and destroy the door, a replacement prehung door can be installed in the metal frame in less than 15 minutes.

After fabrication, all panels and components will receive a coat of white primer to help seal and protect the wood. Nuts/bolts are cadmium plated so they won’t rust and do not need to be primed. The nuts and bolts are the only loose parts. All other parts are fastened to the panels. The ½” bolts and nuts are large enough to be easily found when they are dropped, and robust enough that they threads will not be easily damaged during hundreds of assembly/disassembly cycles.

The primary structure components are simple and complete. When our equipment is delivered, there is NOTHING else your people will need to immediately assemble and use it. We include:

48” Wall Panels, with fabricated steel corner braces and connection bolt reinforcement plates

24” Wall Panels, with fabricated steel corners braces and connection bolt reinforcement plates

48” wide panels with a 36” wide prehung (installed) wood door, Structural steel tube frame

“Short” Steel Angle pieces for inside or outside corners, precision laser cut holes and forming

“Long” Steel angel for 3 way “T” connections, precision laser cut holes and forming

Fabricated steel Channel for 4 way connections, precision laser cut holes and forming

ALL field connections are made with ½” diameter structural bolts and nuts

ALL panels will connect to ALL other panels

2 INDUSTRIAL quality 3/8” drive battery impact wrenches with a charger and 2 batteries each

2 3/8” drive x ¾” DEEP impact sockets and 2 ¾” Professional grade end wrenches

12” long Spikes with 4 lb hammers to stake the panels to the ground

Clamps for Overhead Bracing, and

1 Bucket with spare nuts and bolts.

WARRANTY

MGM warrants that the components in this system will be of the highest quality commercially available materials, and that the craftsmanship used in their assembly will also be the highest quality. Any defects will be easily identified during the first 1 or 2 “set ups”, and MGM will immediately and at no charge (including freight) provide a replacement component.

Regarding “Damage From Routine Use”, this facility is going to be used by ass kickers, who are used to bulldozing their way through doors and walls. The walls will be of better construction and structural strength than a typical residence because we are using OSB instead of drywall. I absolutely guarantee that, if the structure is being used as intended, it will provide good service and value for at least one year.

MGM has erected structures from AK to FL, from CA to VA, and many locations in between. On ANY job, the most significant waste of time is not having everything you need to actually DO the job. Our motto is Leave nothing to chance. Based on our years of experience working in remote locations, we have included EVERYTHING that your people will need to be operational the first day, and probably within a few hours of receiving the system. If you want us to come and help them set it up the first time they use it, say the word and we’ll be there.

Thank you for your consideration.

Mike Gibson, President

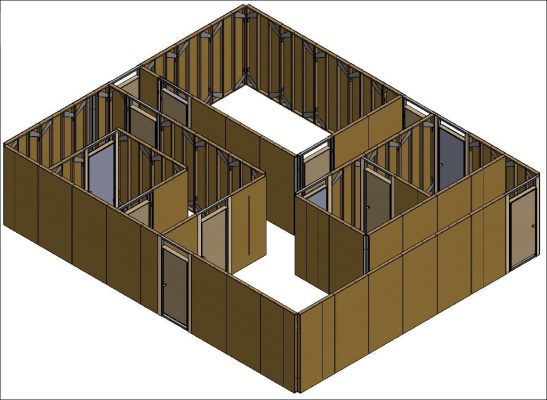

Click the images to see the dimensions for these examples.

Free standing Portable Simunitions Shoot Houses

Portable Simunitions Shoot House for an existing building

Portable Simunitions Shoot Houses at an Intersection

Miscellaneous Construction Documents

Portable Simunitions Shoot House Specs and Overview

Portable Simunitions Shoot House Quick Start Erection Instructions

Portable Simunitions Shoot House Erection Drawing

Portable Simunitions Shoot House Door Determination

Only logged in customers who have purchased this product may leave a review.

Related products

Ranges, Towers, and Shoot House

Reviews

There are no reviews yet.